Nikon Corporation has introduced two new flat panel display (FPD) lithography systems, the FX-88SL and FX-88SLD, both equipped with UV-LED light sources engineered to combine exceptional resolution with enhanced energy efficiency for the next generation of display panels. Orders for the systems begin in November 2025, with commercial availability expected by late 2026.

Replacing Mercury Lamps with Sustainable UV-LED Illumination

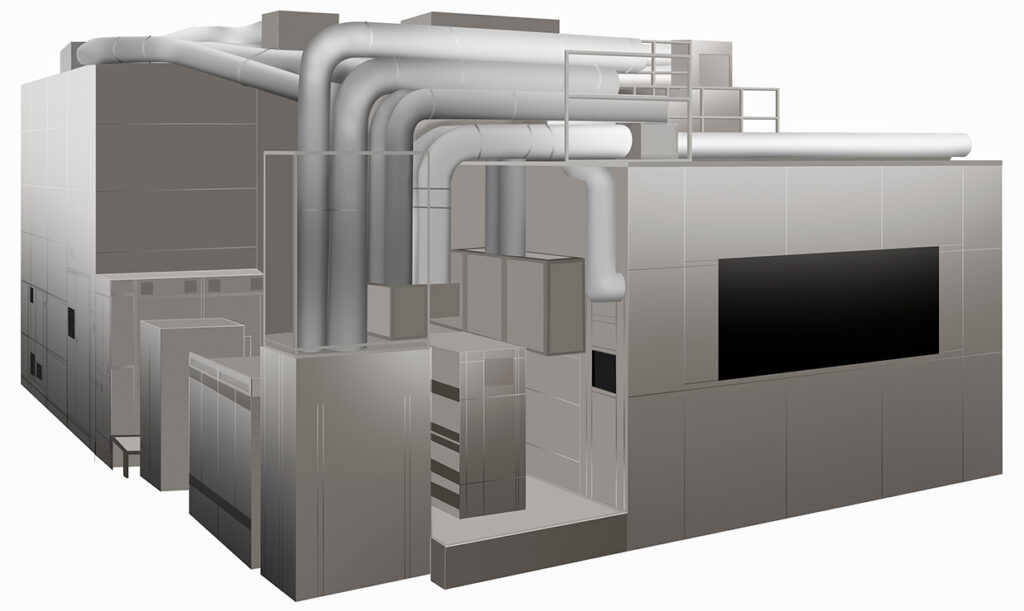

According to Nikon, the FX-88SL series marks a major leap in sustainable semiconductor and display manufacturing. By replacing conventional mercury lamps with UV-LED illumination, the systems deliver reduced energy consumption, longer operational life, and lower maintenance costs—all while achieving higher patterning precision for display applications.

Two Models for Different Applications

The FX-88SL is designed for general panel manufacturing processes, while the FX-88SLD caters to advanced display technologies that demand ultra-fine pattern accuracy, such as OLED and micro-LED panels. This versatility positions Nikon’s new systems to serve a wide range of manufacturers in the evolving display technology ecosystem.

Commitment to Innovation and Environmental Responsibility

“These systems embody Nikon’s commitment to innovation and environmental responsibility,” the company stated. “By combining cutting-edge lithography performance with eco-friendly technology, we aim to empower our customers to meet growing demand for high-quality, energy-efficient displays.”

Expanding Nikon’s Role in the Global Display Market

Nikon’s latest innovation reinforces its investment in next-generation manufacturing tools amid a rapidly expanding global display market spanning consumer electronics, automotive, and industrial applications. With the FX-88SL series, Nikon continues to advance its legacy of precision engineering while adopting sustainable production technologies that align with the future of the FPD industry.